| Item | Detailed Specification |

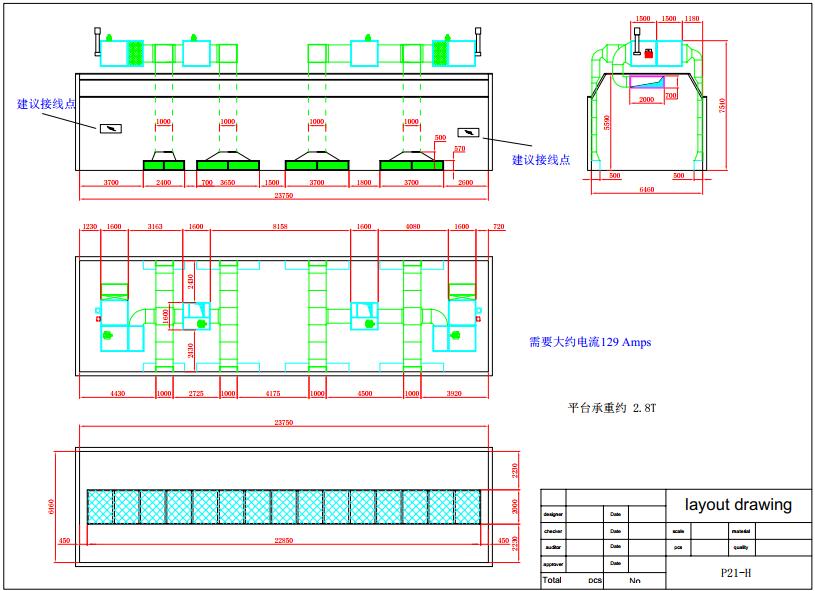

| Inside dimension | 23750×6460×5590 mm (L×W×H) |

| Front door | As the existing construction |

| Emergency door | As the existing construction |

| Basement | Without basement, sides draft. |

| Wall panel | As the existing construction |

| Light | Ceiling Lights: 20Units×4Pcs=80Pcs×16W, side lights: 40Units×2Pcs=80Pcs×16W, with Explosion Proof Lights, lighting boxes are powered coated. |

| Generator cabinet | Inlet from side upper, exhaust from back upper, galvanized steel frame; white coated steel outside, galvanized steel inside, filled with heat preservation material in the middle. The support platform for air unit made by client. |

| Intake and Exhaust system | Inlet: 2×11KW centrifugal fan, belt drive, power: 11KW, air capacity: 28000m3/h.explosion proof motor, with electric damper. |

| Outlet: 2×11KW centrifugal fan, belt drive, power: 11KW, air capacity: 28000m3/h.explosion proof motor, with with electric damper. |

| Heating system | Riello gas burner RS5, stainless steel heat exchanger, electric damper for circulation, max heating productive 260000kcal/h for each, with fire damper. |

| Purification system | Pre-filter, ceiling filter, fibreglass filter, active carbon pocket filter. New ceiling filter like a overhead ducting system. |

| Roof | As the existing construction |

| Control system | Spraying, heat spray, baking, time setting, lighting switch, failure indicator, temperature controller, power supply switch, emergency stop. with inverter, No touch screen control, 2 temperature probes, 1 in the spray booth and 1 outside, to display the temperatures on a temperature controller. If the internal temperature is 10 degrees Celsius higher than the outside temperature, then the emergency stop will automatically activate, If the emergency stop is activated, alarm RED light on, with back up battery for lights and electronically recorded. |

| Total power | 48KW (Power supply 3*380V, 50HZ) |